Discover

Online customer magazine with in-depth reports, best practices, news, trends and interviews relating to the maritime and energy industries.

Browse through the latest articles

Results: 0

-

Alternative fuels trafigura

Alternative fuel expert Rasmus Bach Nielsen reveals how a carbon levy willl unlock the potential of e-fuels.

-

Inflation reduction act CCUS

The Inflation Reduction Act provides increased funding for climate efforts in the U.S. spurring manufacturers to increase production of green technologies including CCUS.

-

Ammonia engine testing

Engineers are developing a two-stroke, dual-fuel ammonia engine that can reduce a ship’s emissions to zero.

-

Methanol GenSet

Engineers in Denmark are making shipboard power low-emission with the developing of a four-stroke methanol engine.

-

Shipping Decarbonization Study

With revised IMO targets, a new MAN Energy Solutions’ study looks at the best technological and financial options to decarbonize maritime transportation

-

Gas engine power plant in Chemnitz

Find out how two gas engine power plants in Chemnitz, Germany, are cutting CO2 emissions by 60 percent and paving the path for a carbon-free future.

-

Methanol fueled ships

Sustainable shipping starts now. Find out more about the first large-scale engines for container ships run on green methanol.

-

Haru Oni e-fuels

The Haru Oni demonstration plant could pave the way for a viable alternative to fossil fuels: It produces synthetic e-fuels from hydrogen that can help the fight against climate change. MAN Energy Solutions provided the e-methanol reactor to the plant.

-

Esbjerg Heat Pump

How a seaport town in Denmark is decarbonizing district heating with seawater and large-scale industrial heat pumps.

-

Upgrading your fleet for future fuels

MAN Energy Solutions experts on the climate impact and business case for converting ships to dual-fuel engine operation.

-

Ethical hackers

MAN Energy Solutions takes a security-first approach to their products, employing ethical hackers like Felix and Nico Lindner at Recurity Labs to uncover vulnerabilities throughout the development and operation of their products.

-

H-TEC SYSTEMS: The hydrogen electrolyzer pioneer

Under new leadership, PEM electrolysis pioneer H-TEC SYSTEMS is scaling up electrolyzer production to meet the growing demand for green hydrogen.

-

Buildung a hydrogen engine

MAN Energy Solutions expert Matthias Auer on developing hydrogen-capable, gas-fired engines for power plants.

-

shipping-emission-overshoot

Shipping is annually making large withdrawals on the carbon budget – so large they probably cannot be caught up.

-

bellona-carbon-capture-storage

Carbon Capture and Storage is one of the necessary building blocks to achieve carbon-neutral industry, says Erika Bellmann of NGO Bellona.

-

The route to climate-neutral shipping

Volker Quaschning, Johannah Christensen and Christopher Hebling address solutions to decarbonize maritime shipping with e-Fuels.

-

ETES heat pump

Danish utility DIN Forsyning is using an innovative solution with new ETES heat pump technology to decarbonize heating for an entire town.

-

Carbon capture utilization storage

Carbon capture, utilization and storage will become more important for the energy transition as unavoidable emissions move to the forefront of discussions.

-

Learning from machines

The autonomous operation of turbomachinery, assisted by machine learning and remote diagnostics, will boost efficiency and help decarbonization.

-

Creating a cleaner fuel

Synthetic natural gas (SNG) and methanol can bring renewable energy to sectors where direct electrification isn’t possible or practical. Here’s how they’re made.

-

Sustainability is a mindset

Eastern Pacific Shipping’s COO Capt. Anil Singh reveals how the shipping giant is cutting greenhouse gas emissions with newbuilds and retrofits for alternative marine fuels.

-

Can methane slip be controlled

MAN Energy Solutions expert Gunnar Stiesch tells us how we can reduce methane slip in two-stroke and four-stroke engines for cleaner shipping with LNG.

-

An ancient craft with modern technology

The MAN Energy Solutions foundry, now open to outside customers, specializes in casting up to 120- ton large iron parts.

-

Put a little salt in your energy mix

The concentrated solar power project in Jülich, Germany, adds a second solar tower with a molten-salt receiver and storage solution for dispatchable renewable energy.

-

Making the maritime energy transition

The work being done on carbon-neutral engines at the Research Centre Copenhagen in Denmark is crucial for the maritime energy transition.

-

A new milestone towards sustainable shipping

In a technical showcase the ElbBLUE became the first container ship worldwide to use climate-neutral synthetic natural gas on a commercial trip.

-

The benefits of methanol

What makes methanol so attractive for the maritime energy transition? MAN Energy Solutions fuel expert Kjeld Aabo explains.

-

Designing the engines of the future

The time is ripe for the sustainable engine solutions of the future. Here’s how MAN engineers are developing engines running on green fuels.

-

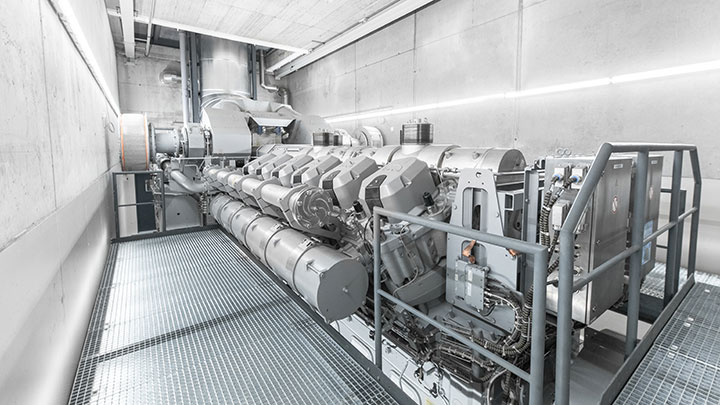

Combined Heat and Power systems for the future

How combined heat and power plants support a German city to reach its target of climate-neutral power and heat generation until 2035.

-

Heating up renewable energy storage

Energy-expert Professor Manfred Wirsum on decarbonizing how we heat and cool the places where we live and work.

-

The art of sustainable production

Behind the practices making climate protection a fundamental part of our manufacturing.

-

LPG makes waves in green shipping

Pontus Berg of BW LPG talks about retrofitting vessels with greener dual-fuel LPG engines.

-

The cost of zero-emission shipping?

Global Maritime Forum’s Johannah Christensen on e-fuels, Covid-19 and a trillion dollar investment.

-

Storing carbon emissions underground

Canada’s first commercial CO<sub>2 </sub>capture and storage facility shows industry how to reduce emissions.

-

What the future holds for shipping

Can shipping halve emissions by 2050? We look at four scenarios with four very different outcomes.

-

Energy management for a smart planet

As power systems become more complex, here’s how industries can manage future energy needs.

-

The case for two-stroke ammonia engines

Why newbuild and retrofit ammonia engines are key for the maritime energy transition.

-

Commissioning goes digital

When the pandemic forced engineers off site, they launched a historic remote commissioning operation.

-

Sun and wind in Africa are the new oil

Why tapping Africa’s vast renewable energy resources would be an economic boom for the continent.

-

The green fuels of Africa

How hydrogen won from Africa’s vast wind and solar resources can revitalize the energy transition.

-

Why digital experts love industry

Young professionals on working at the frontline of digitalization in mechanical engineering.

-

Welcome to a new green hydrogen economy

Hard to electrify? Why scaling up Power-to-X will provide massive immediate carbon reductions.

-

The many forms of decentralization

Hybrids, CHPs and peaker plants: How decentralized power generation brings reliable, cleaner energy.

-

How to build a power operation from scratch

MAN experts tell what it takes to create new plants on Indonesian islands far off the beaten track.

-

Powering this side of paradise

What does electricity mean to islanders in Indonesia? We traveled to remote Sumbawa to find out?

-

FROZEN – The world of cryogenic fuels

Meet the Swedish cryogenic-fuel experts that are having fun greenifying shipping

-

How to store sustainability

No sun or wind? No problem. Here’s how zero-carbon energy storage tech will drive decarbonization.

-

Climate change strategy for shipping

What ship owners, builders and regulatory agencies can do to cut emissions in shipping by 50 percent.

-

Here comes the green hydrogen boom?

The International Energy Agency’s Timur Gül on e-fuels and how we’ll bring them to scale.

-

The art of green hydrogen

For decades this company has been perfecting the tech that turns renewables into green hydrogen.

-

When cars cross oceans

200 meters long and 13 car decks high these new mammoth car carriers run on LNG.

-

Augmented reality for Canadian seafarers

Spend an hour inside the Royal Canadian Navy’s virtual reality training for their new patrol ships.

-

Shining a light on a smart island

How the remote Faroe Islands are using a microgrid to become 100 percent green in the next decade.

-

Making fuel from sunlight and air

This mini-refinery above the rooftops in Zurich captures carbon and solar power to create clean fuel.

-

Climate-friendly engines go fishing

The first LNG-powered fishing trawler nets industry attention for its big emission reductions.

-

The journey of a 325-ton engine

CHP engines bring steam, power and efficiency to the heart of a booming Honduran textile industry.

-

How can we decarbonize shipping?

Hapag-Lloyd’s Richard von Berlepsch on climate change, clean oceans and LNG for cargo ships.

-

City sees energy systems as a whole

Can the German city of Hamburg become a model for the sustainable city of the future?

-

Cleaner energy for Rock of Gibraltar

When Gibraltar upgraded its nearly 40-year-old power system, they opted for a unique LNG solution.

-

Designs for a livable future

Giant kites and smog-sucking towers: Can socially-oriented designs create a more sustainable world?

-

Automated subsea platform for deepwater compression

The world’s first subsea compression system has revolutionized oil exploration; learn how automation and digitalization make it cleaner and more efficient.

-

Pioneering retrofit to reduce emissions

First European diesel-powered dredger converted to dual-fuel operation which makes it more energy-efficient and cost-effective.

-

Energy transition – concrete steps to combat climate change

Which future fuel solutions do we need to reach our climate goals? VDMA expert Matthias Zelinger on solutions towards global decarbonization.

-

Innovation inspired by nature

By learning from and emulating nature’s solutions, biomimicry can help solve complex human design and engineering problems.

-

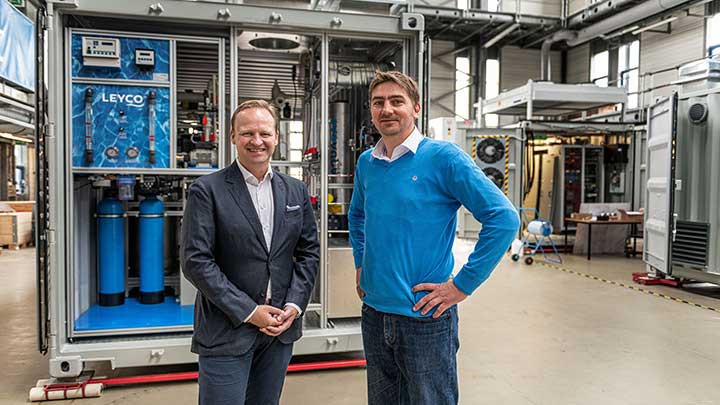

Combined Heat and Power

A new combined heat and power (CHP) plant delivers a flexible and efficient energy solution that saves up to 60,000 metric tons of CO2 per year.

-

Extreme engineering

MAN PrimeServ provides engineering field service all over the world, sometimes in areas classified as hostile environments. Here’s how engineers work under extraordinary circumstances.

-

Logistical challenges

We go the extra mile to face logistical challenges, surmount transport obstacles and solve technological problems. Some of our most challenging projects.

-

Power-to-X

Power-to-X is the carbon-neutral energy storage and sector coupling technology of the future: Our actions within this decade will decide whether we are able to reach the ambitious goals of the Paris agreement.

-

-

Fueling growth in Bangladesh

A power plant near Bangladesh’s capital is helping the emerging country meet its growing energy requirements.

-

Setting sail for a sustainable future

The IMO sets targets for decarbonization. Here’s how marine shipping can help achieve climate goals.

-

World’s largest fusion reactor

In southern France, a cast of thousands is working to change the future of sustainable energy.

-

A roadmap to the green zone

The first container ship converted to LNG offers real insight into making the industry carbon-neutral.